ABoUT US

VI-TECHNIK specialises in rubber, plastic and glazing components for the automotive, defence and rail industries

Specialising in quality control and quality management, VI-TECHNIK has developed a wide range of turnkey solutions. Our strategy is to support companies along their entire supply chain in order to optimise quality and economic performance.

The quality services we provide from OEM’s plant are:

- Limitation and inspection of supplies with quality problems;

- Implementation of specific quality control protocols;

- New processing of supplies, packaging, cleaning of components;

- Management of the Controlled Shipping Level (CSL);

- Quality engineering services provided by a highly qualified staff, specially trained in nonconformity management, failure occurrence analysis, and development and support when managing plans for product quality improvement;

- Site/resident engineer services.

VI-TECHNIK IS AN APPROVED FCA SOURCE

FOR CSL2 AND CSL3 QUALITY PROTOCOLS

Thanks to our diversified support strategies, we offer truly cost effective, efficient solutions for the provision of technical-qualitative support as Supplier Quality Engineer (SQE) Service. Thanks to our site/resident and local regional engineers we offer big advantages for your business. We:

- build relationships with the customer’s plant and then with the Quality, Logistics and Production Department staff;

- inspect any fault, no matter how small, mentioned by the customer and provide a detailed description of the problem, complete with high definition pictures and product identification data;

- discuss any possible concerns reported by the customer, in order to carry out a complete investigation which explains out all aspects of the problem found;

- support our customers to work out an acceptable correction and plan of action, and draw up the 8D report.

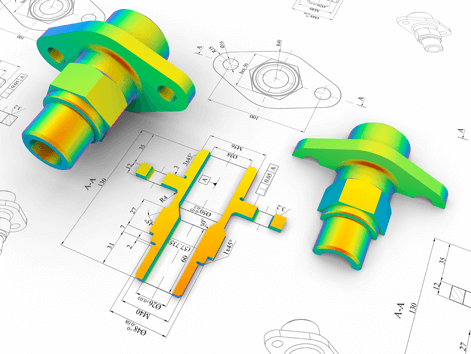

We also offer fast prototyping services and limited production of plastic and rubber components using standard material and equipment. Our machinery capability of vertical and horizontal injection machines from 20 to 320 Tons, our service is distinguished by the speed in which we make prototypes with mass production materials and technologies which will be used in the future for mass production.

We can supply thermoplastic and rubber materials for extrusion and moulding technology in a very short time and in limited quantities. Parts are used in order to validate the project phase, to prepare proto-vehicles, or to support the customer before mass production begins. Our range of fast prototype production also includes small-sized metal components (in steel and aluminium). We supply a full range of surface treatments such as RAL or PANTONE coatings, films applied to extrusion-moulded components, chromium-plating, aluminium-plating, and galvanic coatings in general.

Our services are mainly focused on the research & development phase of interior and exterior trims in the automotive and transport industries in general. We plan and assist our customers as they design and process elements such as: body parts, mobile parts, sun roofs, gaskets and mouldings.

OUR NUMBERS SINCE 2015

Customers served

Automotive projects developed

Performed inspections

Countries served

Registered office VI – TECHNIK s.r.l

at Polo Tecnologico

in Pordenone “Andrea Galvani”

Via Tolmezzo, 9 – 33078 San Vito al Tagliamento (PN) – Italy

Offices

SITE 1: Via Tolmezzo, 9 – 33078 San Vito al Tagliamento (PN) – Italy

SITE 2: Via C. D’Aguanno snc – 03030 Piedimonte San Germano (FR) – Italy

SITE 3: Istanbul Caddesi, Bursa, 16210, Türkiye

Ph: +39 0434 85054

E-mail: info@vi-technik.com